About Us

Who We Are

Who We Are

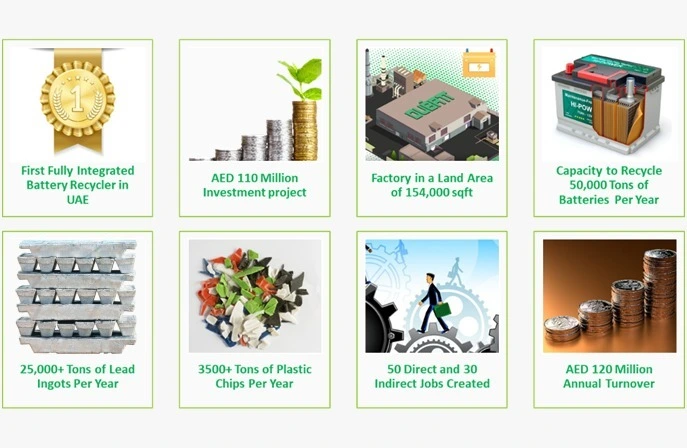

UAE's first Battery Recycling Facility

Dubatt is the first fully integrated Used Lead Acid Battery (ULAB) Recycling Facility in UAE. With a factory spread across an area of 150,000 sqft and capacity to recycle up-to 50,000 metric tons per year, Dubatt is the only ULAB recycler in UAE and one of the largest facilities in the region.

Dubatt was incorporated with Inspiration from the Dubai Integrated Waste Management Strategy 2021-2041 envisioned by H.H Sheikh Hamdan Bin Mohammed bin Rashid Al Maktoum, Crown Prince of Dubai, and chairman of the Dubai Executive Council.

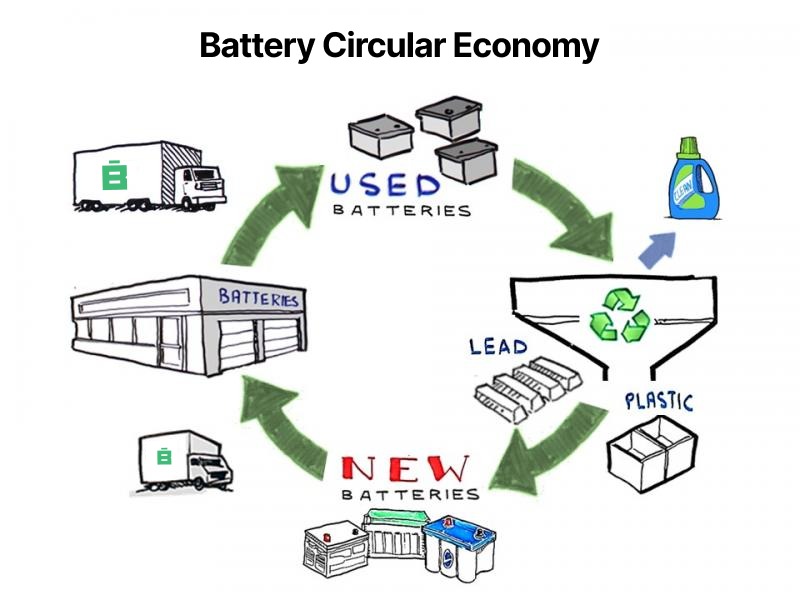

We recycle the Used Lead Acid Batteries in our state-of-the-art factory at Dubai Industrial city and manufacture value added lead metal products that are sold as raw material for new battery manufacturing. This way we energize and contribute to the UAE Circular Economy Policy, UAE Sustainability Goals, and the “Make in Emirates” initiatives.

Why Recycle ULAB

Why Recycle ULAB

- UAE generate around 60,000 -80,000 metric tons of Lead Acid Battery Scrap Per year. These are hazardous waste and if not recycled in an environment friendly manner, they create huge environmental and health hazards.

- Lead metal constitutes around 70% of a typical lead acid battery. Lead is a known carcinogen (can cause cancer in people). Sulfuric Acid is the common electrolyte in batteries, and this also need to be neutralized in a safe and scientifically approved and environmentally safe manner.

- UAE is a member of Basel Convention for Transboundary movement of Hazardous waste. Basel convention highly discourages transboundary movement of battery scrap and regulates the movement of these hazardous wastes. The member countries are obliged to ensure that such wastes are managed and disposed of in an environmentally sound manner and ensure they are transported and recycled/treated as close as possible to where they were generated (within the country itself) and to minimize the generation of hazardous waste at source.

- Being the first ULAB recycling factory, Dubatt has enabled in creating a solution for UAE to recycle the hazardous waste of battery scrap within the county and create value out of this waste. Our factory is equipped with the best of Italian technology in our machinery we follow the industry best available technology (BAT) complying with all environment norms in our factory. We employ the best of professionals with a collective experience of 280 years in ULAB recycling to ensure maximum productivity in the most safe and sustainable process and practices at our facility.

What We Do

What We Do

Lead Acid batteries are hazardous in nature after their end of life as they can create land, water and air pollution if not recycled properly.

As such lead acid batteries are one of the most recyclable materials as it is possible to reclaim around 90% of its weight as reclaimed lead, plastic and other bi-products which are used extensively for manufacturing of new batteries and applications in fishing, medical and other industrial sectors.

Dubatt is the First Fully Integrated Used Lead Acid Battery Recycling Facility in UAE. We have a capacity to recycle 25,000 metric tons of batteries and produce around 14,000 tons of Lead, 1750 Tons and Other Bi-products.

How we recycle

How we recycle

The Recycling process of Used Lead Acid Batteries can be categorized to 3 stages :

-

Battery Breaking & Separation

Batteries are Crushed in a hammer mill and undergo a process called hydro separation in a series of machineries to separate the various components as:

- Lead paste & terminals

- Polypropylene chips (PPE Plastics)

- Gypsum from the Acid Neutralization process

-

Smelting

Preparation of charge (lead grids and lead paste) along with other reagents/chemicals and charging to the rotary furnace and recovering of the metal as jumbo lead bullions.

-

Refining

Further refining of the lead bullions to yield refined lead ingots and lead alloys as per customer requirement which then goes for manufacturing of new batteries.